Particulate Matter Sensors [1]

Particulate Matter Sensors (PMS)

What technicians need to know about the increased use of Particulate Matter Sensors (PMS) now utilized on increasing numbers of Diesel-powered vehicles.

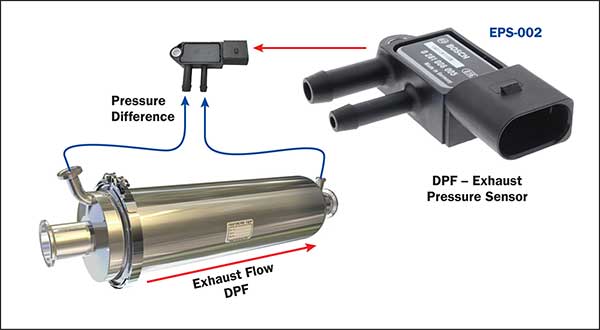

Currently, for Diesel-powered vehicles to meet Emission Legislation Standards in Europe and USA, they are generally fitted with an exhaust trap/filter for Particulate Matter. (DPF – Diesel Particulate Filter). Monitoring the levels of restriction in the DPF can be provided by evaluating the pressure difference across the filter by the "DPF - Exhaust Pressure Sensor" as required by in-use monitoring (OBD), to ensure the efficiency of a functioning DPF through a regeneration process.

Particulate Matter Sensor (PMS)

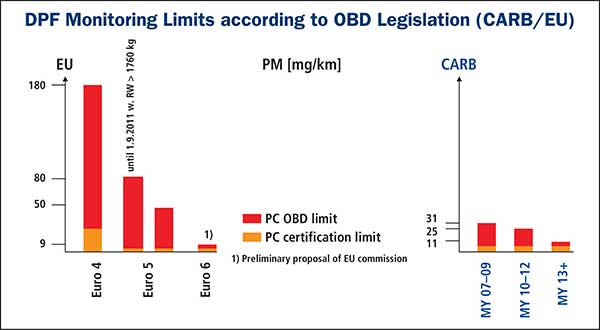

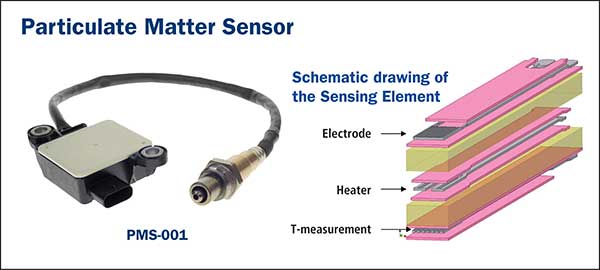

With the continuing tightening of emission regulations for Diesel engines, a more direct measurement of particulate matter is required that provides sufficient accuracy and sensitivity with the structure necessary for stable long-life operation, whilst dealing with exhaust gas conditions.

Life Span – 250,000km Max Exhaust Temperature 850 Deg C

The particulate matter sensor can assist in:

- The estimation of the amount (Mass) of soot accumulation in the DPF for a more accurate DPF Regeneration strategy.

- DPF failure detection process which may result in excess PM emissions, to log an OBD fault signal.

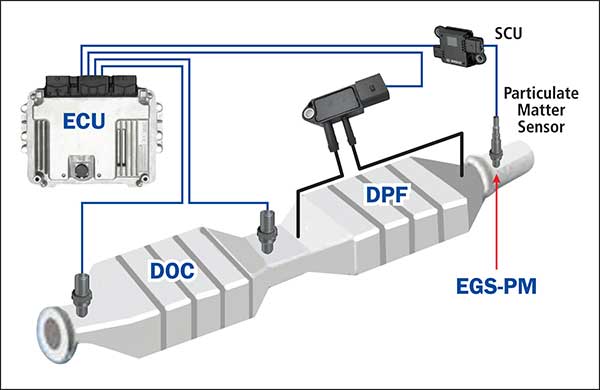

The Bosch ceramic Exhaust Gas Sensor for Particulate Matter (EGS-PM)

The simplified basic operation of accumulative electrode type PMS:

- A DC voltage is applied to 2 inner – digital electrodes on the sensing surface.

- As soot particles from the exhaust are deposited during engine running condition, the characteristic drop of resistance due to the build-up of “electrically conductive soot particle paths” can be used to determine soot emissions. (Based on the varying resistance measurement)

- Prior to each measurement phase, an integrated heater and temperature sensor allow for controlled regeneration of the sensing element” (Removal of soot through oxidation) by heating.

Note: Other sensing technologies may be utilized to achieve a similar result.

Typically

- Electrical charging sensor

- Radio Frequency (RF) sensor

Location of PMS:

The particulate matter sensor is generally installed downstream of the DPF and combined with an Adapted sensor control unit (SCU).

Testing the PMS system requires a suitable scanner, but it is essential that the Diesel Particulate Filter Is in a functioning condition.