What a technician needs to know about the various effects on the engine management system and how to correctly carry out a diagnosis and identify the results when the FPR becomes faulty.

Note: Refer to previous article for Fuel Pressure Regulator types and operation for the various fuel supply systems.

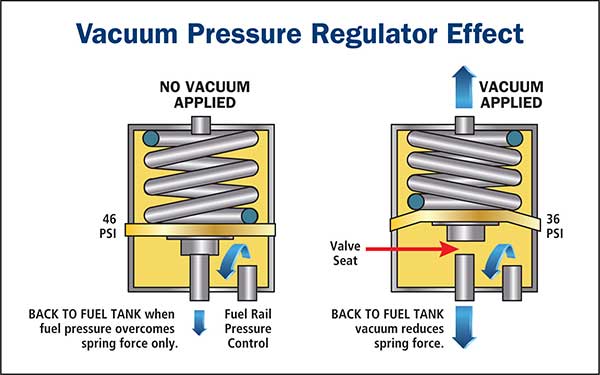

Typical vacuum affected FPR operation.

Simplified typical common faults associated with an FPR fitted to a standard EFI system.

Generally, when a typical FPR fails, the result will generally create a:

- Leaner than normal mixture due to an incorrect lower than normal pressure created by a sticking (open) internal FPR valve, an incorrect FPR unit fitted or a perforated diaphragm on an FPR unit that is located internal of the fuel tank.

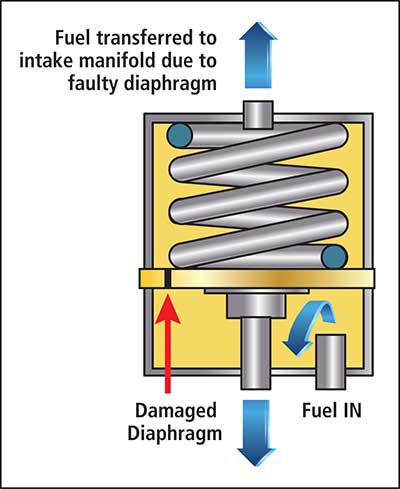

- Richer than normal mixture due to an incorrect higher than normal pressure created by a sticking (closed) internal FPR valve, incorrect FPR unit fitted or a perforated diaphragm on an FPR unit that is located external of the fuel tank (generally on the fuel rail) and transferring the leaked fuel to the intake manifold via the vacuum hose. (also causes a hard to start condition due to excess fuel).

- Delayed engine start up due to the loss of residual fuel pressure and fuel stored in the fuel lines caused by a leaking check valve seat in FPR allowing the fuel to drain back to the fuel tank.

Simple tests to be carried out to assist in determining if the FPR is causing incorrect mixtures.

When a diagnostic procedure is to be carried out on a vehicle that has performance issues, the technician needs to determine the correct cause/s to eliminate continuous parts replacement due to inconclusive diagnosis.

Typical fuel mixture related fault codes that can be problematic in the engine performance diagnostic process are typically (P0171 and P0174). Both codes relate to lean running / fuel mixture conditions for Bank 1 (P0171) and Bank 2 (P0174).

There are of course multiple causes for these codes and the technician requires a systematic approach to determining the cause.

Typically, the symptoms that the vehicle would exhibit are:

- Increased fuel consumption

- Check Engine Light will illuminate

- Rough or high idle

- Decreased acceleration

- Engine stalling

Typical tests to be carried out to assist the technician:

Perform a fuel pressure test.

Correct fuel pressure and flow must be verified prior to carrying out further tests. Only after these fuel tests have been confirmed as being correct, would the other tests need be carried out.

Other Tests

Typically:

- Check the intake system and vacuum lines for leaks

- Inspect the valve cover for worn hoses or leaks

- Inspect the PCV valve

- Test the Mass Air Flow (MAF) sensor with a scan tool or multimeter

- Test the related Oxygen (EGO) Sensor with a scan tool or multimeter

There are of course many other possible causes for these codes that would require further testing.

Typically:

- Failed Fuel Injector (INJ)

- Faulty Control Module or fault codes

- Exhaust leak or faulty intake manifold

- Outdated PCM software or faulty code reader

A rich mixture causing performance and stalling problems may log fault codes P0172 and P0175.

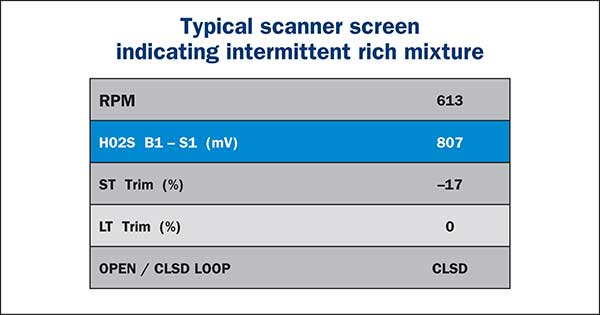

Again, the causes of these fault codes may be due to multiple component or system conditions and monitoring short term (ST) and long term (LT) trim using a suitable scanner can assist the technician in quickly determining the area of fault. These faults may cause intermittent rich mixture conditions or constant rich mixture conditions.

A typical scanner screen indicating an intermittent rich mixture and displaying the short trim reading of -17. (That is reducing the fuel by 17% at this point to try to maintain a correct fuel mixture). The simple oxygen sensor test also indicates a high voltage / rich mixture (807 mV).

This vehicle was fitted with an FPR with a perforated diaphragm that caused the intermittent richer than normal mixture. Removing the vacuum hose from the FPR generally quickly presents the technician with the evidence of fuel.

The ST trim reading varies depending on the amount of fuel that escapes past the FPR diaphragm.